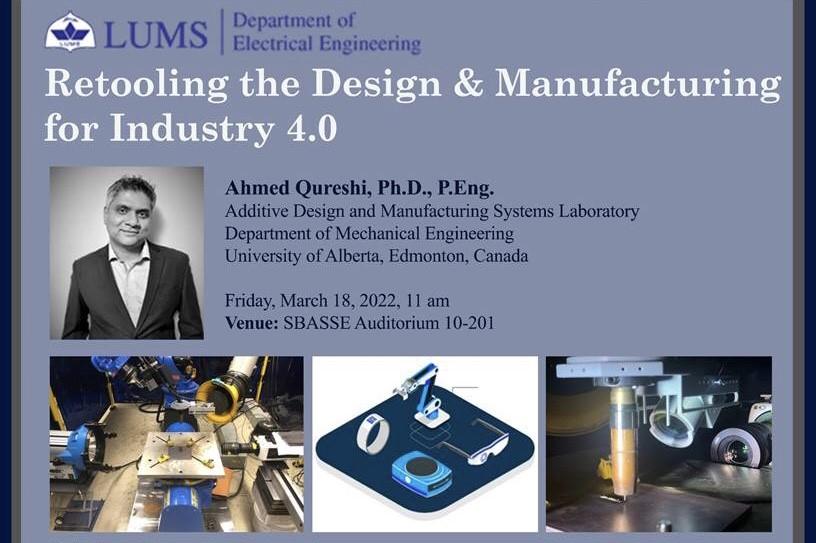

Retooling the Design and Manufacturing for Industry 4.0

• How do we move to design for additive manufacturing, and why should we design for additive manufacturing, rather than trying to additively manufacture what we can make through conventional manufacturing anyway?

• How do we manage, measure, and quantify the geometric variation in the additive manufacturing produce lifecycle?

• How do we innovate and push the technological frontier in large scale additive manufacturing systems engineering and material systems? and,

• How do we integrate multiscale quality assurance and process and product qualification for additive manufacturing?

Dr. Ahmed Qureshi is an associate professor at the University of Alberta, Edmonton, Canada, leading the Additive Design and Manufacturing Systems (ADaMS) Laboratory at the Mechanical Engineering department. He has a bachelor's degree in Mechanical Engineering from UET Lahore, Pakistan, a Master's in Design and Industrialization, and Doctorate in Mechanical Engineering from Arts Et Metiers ParisTech, France. Following the doctorate, Dr. Qureshi worked as a research associate at the University of Luxembourg and a lecturer at the Newcastle University UK and its Singapore campus. Dr. Qureshi's research interests are in advanced design and manufacturing, focusing mainly on additive manufacturing systems engineering, design for X, and quality and qualification in manufacturing processes. His recent research projects include systems engineering projects for plasma transferred arc AM system for AM of Nickel-Tungsten Carbide parts, development of novel 4D ferromagnetic polymer-metal composite material jetting systems, and multi-degree of freedom robotic wire arc additive manufacturing systems for supportless printing. Dr. Qureshi also has extensive experience in quality assurance and control of mechanical and geometric properties of 3D printing/Additively manufactured parts. Dr. Qureshi's lab also innovates in digital design and manufacturing chains. This includes developing algorithms and software for additive manufacturing, reverse engineering, and computer-aided path planning.