Packaging – Thinking Out of the Box for a Sustainable Planet

Introduction to the Environmental Science (SCI-103) is an introductory course taught by Dr. Fozia Parveen at Syed Babar Ali School of Science and Engineering. This elective course was designed as a standalone course for students of all levels from all across LUMS in order to understand the complexity of environmental issues and encourage individuals to be active agents of change for a sustainable planet. Change within and without as is need of the time. The course aims at establishing a link between an individual and their hydrosphere, geosphere, atmosphere, and biosphere to bring about the much-needed sensitization through science.

In order to get a better understanding of the issues and to propose relevant solution at the end of the course, Dr. Fozia took her students to visit one of the large packaging factories in Lahore – Packages Limited. The activity comprised of visits on two consecutive Saturdays where around 50 students of the class accompanied by the faculty visited the factory site in Lahore. These visits took place on 2nd and 9th of October 2021. As the course aims to offer an experiential learning experience for students, after learning about renewal and non-renewable resources of energy and plastic as a byproduct of fossil fuel, it was about time for the students to get a sense of scale of the industrial processes with a focus on the environmental inputs and the impact on the environment as a result of the industry. The visit was followed by an assignment for student to submit their observations and recommendations.

The students were given a presentation by the lead engineers, who also chaperoned the students throughout the various areas of the factory. The students were able to get a first-hand experience of how paper printing and plastic printing is done for the everyday products which we consume day-in-day-out. The host also engaged the students in giving them a better understanding of how they use environmental quality parameters to ensure lesser pollution. They explained how they manage their social impacts and ensure supply chain sustainability throughout their product life cycle by closely working with the suppliers to mitigate potential risk for continual improvement. The power-supply for the entire factory and the adjacent property is being managed by solar power and clean energy.

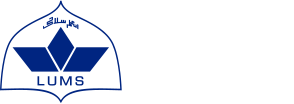

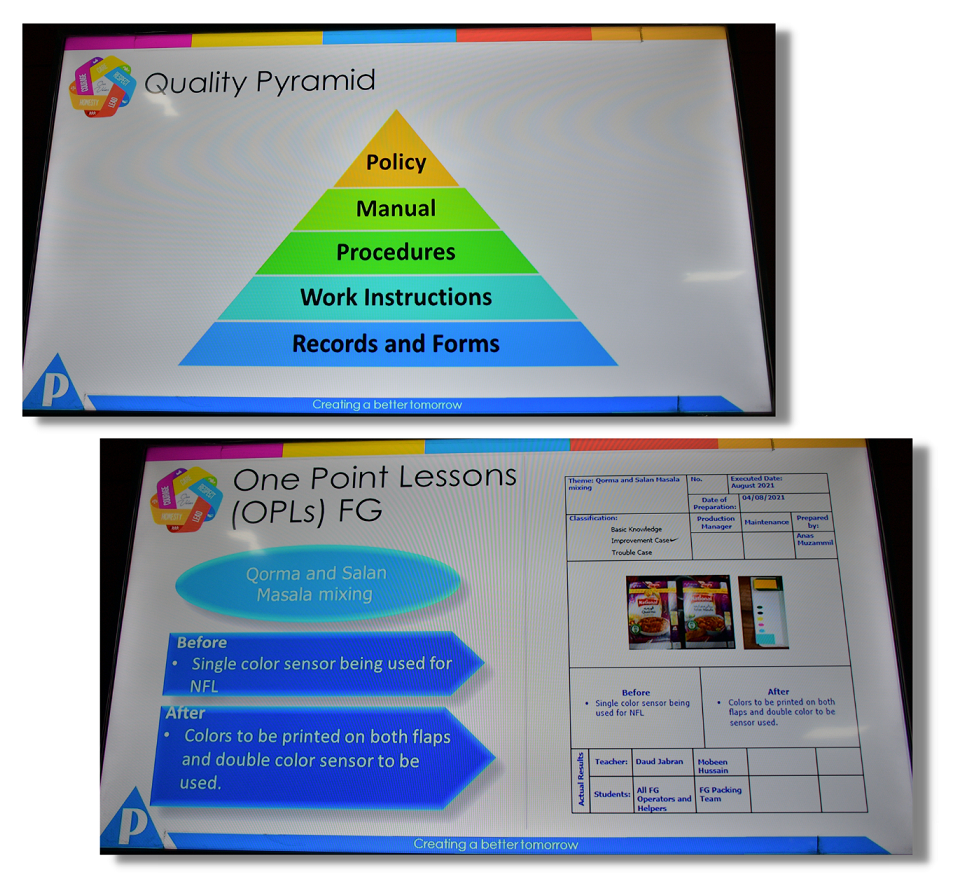

Their two-basic plants are committed to printing of paper material for boxing of goods and products which come in every-day use, while the other plant component is for the plastic wrapping and packaging. To ensure compliance of all rules, Packages has added One Point Lessons (OPLs) within the factory facility, so that all employees understand and follow the required methods. Their quality assurance pyramid represents the hierarchy when the employees operate the assembly-lines and work with the larger-than-life machinery.

Packages Limited has been operational in the country for the past 60 years and the factory while employs thousands of employees, has contributed a lot to the packaging industry in Pakistan. The company employs ethical practices to source and process the material which is used at the site. As part of their risk management systems which the company has employed, they promote workers’ engagement in reducing overall risks related to Environment, Health and Safety including all the associated hazards in their operations. Since a lot of their packaging products are for food related materials, they ensure that all food related packaging material is procured, stocked-up, produced, stored, and delivered in safe and hygienic condition as per applicable standard and customer requirements.

This was an extremely beneficial activity for the students, who could see the on-site examples of how a large factory uses and recycles their material and gave them a greater understating of the impact of such facilities on the environment.

Our students explain the visit in their own words:

“The visit was really helpful in the sense that it gave me a view on how much an industry affects the environment. Seeing the production speed with my own eyes, along with thousands of products being made in an hour, they were also making toxic gases in the same quantity in an hour. As the industry people were very open and shared minor details as well, it helped a lot in getting the detailed info of how things work in real life and we got to get a peek of it, as compared to just reading from the books”, Shiffa Ur Rehman.

“I think the visit was very insightful because it allowed me to not only get an insight into manufacturing processes but also allowed me to expand my awareness on worker conditions, factory priorities (Environment vs. Profits) and the complexity of machines used”, Muhammad Asad.

“This trip was indeed a great learning experience. It gave me an exposure to the pratical working environment and awareness about the industrial practices. Along with great understanding of the packing processes and how plastic and wood (raw pulp) was being processed to the final form and then all the layering of inks to gain final prints, I also got to see how the large amount of plastic and paper was being discarded due to very minute faults. Those faults in the prints were not even visible until the guide showed us.

Apart from this, large amount of energy was being used for the 24/7 operation of machines and only 3-4 MW was coming from renewable resources.

Do we need such industrial visits?

Absolutely! Sitting in class and learning about how environment is being harmed by us humans was indeed great learning but seeing it and listening from people working in big companies like packages added to the information. I believe the information that they gave us during visit could have been delivered through some presentation because of loud noises inside the plant. It could have saved their energy as well because they had to talk very loud to get the point across”, Urooj.

“The trip was extremely informative; I am extremely impressed by the managed system of their industry. I have visited a lot of factories but none of them had their quality check like packages. The staff was well mannered and welcoming as well. Moreover, the way they have reduced their waste to 3.5% is shocking because every industry is bothered about their product rather than how their industry affects the society.

One should definitely have such component in the courses because obviously we all should know what the practical world looks like rather than just sitting in class rooms and talking about what should happen what should not rather than going over there and doing an analysis on how things could be improved. Very impressive”, Bakhtawar.